The Advantages of String Inverter in the Solar Power Station

In recent years, China's PV industry has developed rapidly, and the PV installation capacity exceeds 43GW in 2018. As a highly intelligent unit of PV system, solar inverter is the core equipment in the PV power generation system. During the rapid development of technology period, industries are updating iterations at an extremely fast rate. The current string type PV inverter has a few features, such as: it is more powerful, more intelligent, and also the single inverter’s power capacity has a continuous breakthrough. Recently, many PV projects in China are using 70/80kW inverters. And the higher power string inverters gradually is becoming mainstream. At the same time, in the medium and high voltage grid-connected PV power plants, string inverters also have a tendency to replace central inverters. This article takes the JFY SUNTREE series 70/80KW inverter as an example. To briefly introduce several advantages of the string inverter compared with the central inverter.

SUNTREE 80KTH Inverter

SUNTREE 80KTH Inverter

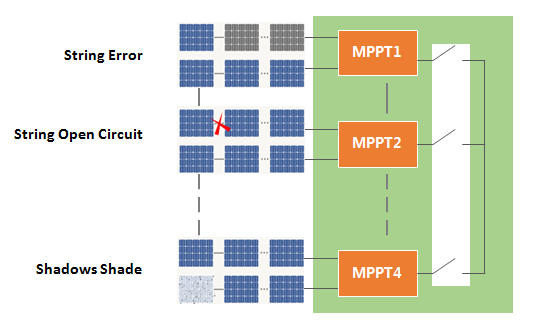

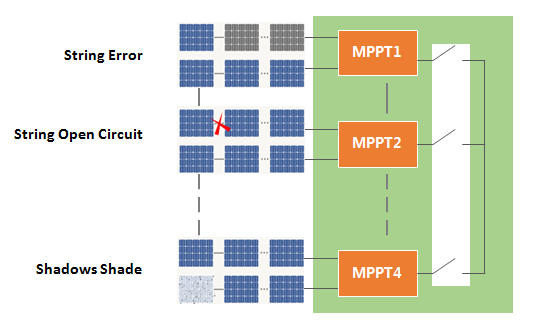

This kind of inverter has more MPP trackers. It adopts 4 MPPT design, which can adapt to the complex installation terrain. In the operation of power station, if there’s partial occlusion or panel failure in one MPPT circuit, the other MPPT circuit won’t be affected.

Saving DC combiner box costs. SUNTREE 70/80K adopts 12 strings of input and fuse protection design, it is integrated DC combiner box function (convergence, lightning protection, switch, anti-reverse connection, etc.), which can connect each solar panel string to the DC input of the inverter directly. There is no need to add additional DC combiner. This will simplify system design and save system cost, and also reduce the risk of failure for the system. It adopts waterproof cooling fan and is completely isolated from the internal circuit board of the inverter. The inverter is IP65 protection grade, which can satisfy outdoor installation conditions. No complicated inverter room (fire, air conditioning, lighting, etc.) is required.

High output voltage, lower cost. With 480Vac and 540Vac as the main output voltage, compared with the central inverter output voltage of 315Vac. It save costs on AC output cables. For the same power, the higher the voltage is, the smaller the current will be, and the lower the loss will be. Therefore, the higher the output voltage is, the less the current-carrying capacity will be for AC cables, which means that cables with smaller wire diameters can be used. Similarly, high voltage grades can also save windings for step-up transformers, thus achieving cost reduction.

Fault positioning is accurate and efficient. Self-contained string monitoring, if part of the module fails in the power station, it will first react to the corresponding inverter. Through the monitoring platform, the current and voltage anomalies on each MPPT loop can be directly read, so that the fault can be located. The positioning of fault is accurate and fast, and the maintenance is convenient, completely eliminating the economic loss caused by large-scale shutdown.

Wide voltage input range. The MPPT input voltage range is from 250Vdc to 850Vdc. On one hand, the single string design is more flexible in the design of the power station. On the other hand, the wide voltage range makes the inverter a longer working time, startup early and shutdown late, which means it will generate more electricity power.

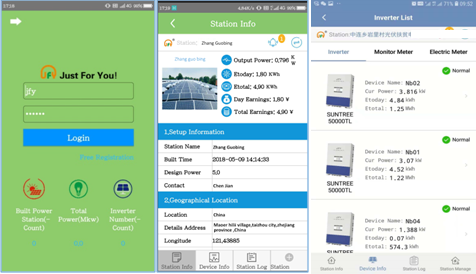

Flexible and diverse monitoring methods, more practical and more convenient. It can be connected to the inverter through RS232, RS485, GPRS/WIFI communication module. Registering JFY monitoring platform is free which can be used to monitor your PV power station through web server or mobile APP. For some users who have insufficient memory of mobile phone or are unwilling to install the APP, they can also monitor the power station by using JFY WeChat public account.

Monitoring interface

JFY was founded in 2003, which is one of the earliest manufacturers of PV inverters in China. It has 10 years’ experience in the PV inverter industry. Looking forward to the future, JFY will continue to promote the cost reduction and improving efficiency of inverters, and contribute to the world green energy.